Direct to Product Digital Printing

Advances in Inkjet head technology have now reached the level where direct to product, single pass, full color, inkjet printing has become a realistic and viable option for 24/7 industrial production processes. The design on demand capability of a digital printing system is well suited for situations where short production runs and frequent design changes are required, as well as in situations where individual product coding or differentiation may be needed.

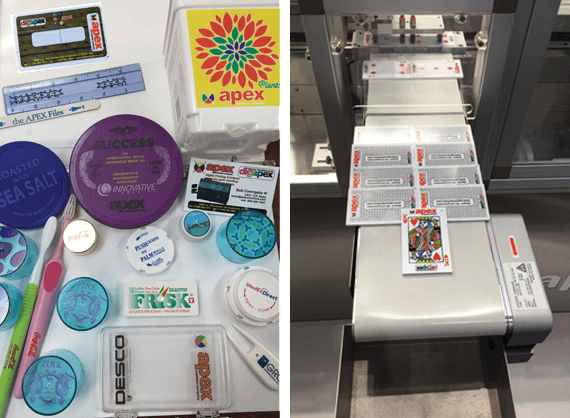

Apex Machine is able to offer some exciting new options for the handling and printing of various different substrates and product geometries. A variety of machine types and handling systems are available and these can be configured for full color CMYK printing, with the option of a white base coat where required. Most machine types can additionally be configured with standard Dry Offset, Flexapex and/or Hot Foiling stations where required.

Further possibilities exist for addition of digital printing stations into existing Apex printing machines in the field to accomplish tasks like product serialisation, barcoding or additional decorating, providing new capabilities and flexibility to meet changing production requirements.

DB1000 Digital - White plus 4 Color Process

This printer series is designed for the handling of a variety of flat parts that can be loaded onto a continuous motion belt for transport through a pretreatment station (where required), a base coat white and UV pinning station (optional), a full 4-color CMYK print station and a UV curing station with automatic unloading after. A variety of loading, unloading and other handling or decorating modules can be provided to meet most requirements.

- Full color capability (CMYK)

- Design on Demand capability

- Optional White Base Coat plus pinning

- High Quality 360dpi or 720dpi printing (Up to 1200 dpi available)

DRT2000 Digital Printer

This printer series is designed for the handling of a variety of flat parts that can be loaded onto pallets for transport via a continuous motion, fully programmable, magnetic linear rail system (Racetrack).

Parts are moved through a pre-treatment station (where required), a base coat white and UV pinning station (optional), a full 4-color CMYK print station and a UV curing station to an automatic unloading station. A variety of loading, unloading and other handling or decorating modules can be provided for most requirements.

- Fully Programmable handling system

- Full color printing capability (CMYK)

- 'Design on Demand' capability

- Integrated barcode driven production batch control system

- Adjustable for a multitude of different product geometries

Technical Specifications

| Maximum print width | 72mm (up to 144mm available) |

| Printing speed | 40 to 100+ parts per minute |

| Print Resolution | From 360dpi up to 1200dpi (print head dependent) |

| Voltage: | All voltages - to suit requirements. |

| Curing Technologies | UV and LED |

| Specialty Inks: | UV and LED optimized for substrates |